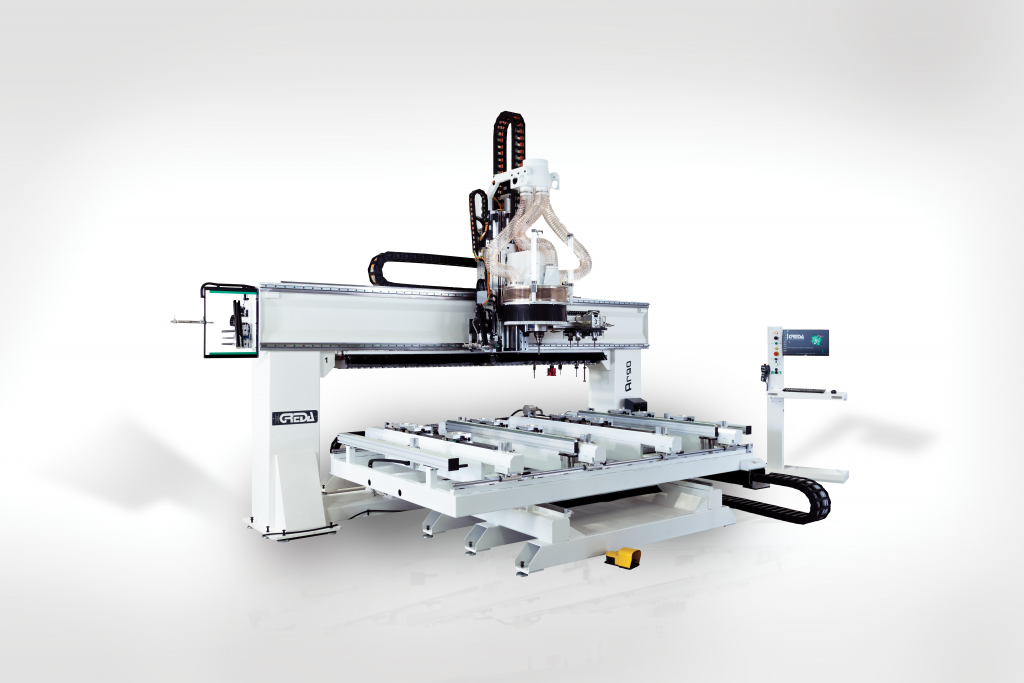

Argo range embraces a new model, especially designed for doors and jambs and able to process honeycomb doors.

Argo Doors is a 5-axis NC-machining center equipped with an AT table top, T-slots and adjustable aluminium benches, and provided with vacuum or clamping systems. The main operating group R1CU allows big removals and provides no less than 36 positions for tool changing.

The peculiarity of such Argo evolution – and that makes it different from Diva Doors, for example – consists in automatic positioning systems and a loading support with anti-scratch system that not only facilitate the operator’s activities, but reduce loading and positioning time, too.

An anuba hinges loader with additional side feeder, a tool-setter to adjust lengths and a 3D dynamic sensor that measures the workpiece complete Argo Doors’ configuration.

How Argo Doors works? Watch the video!